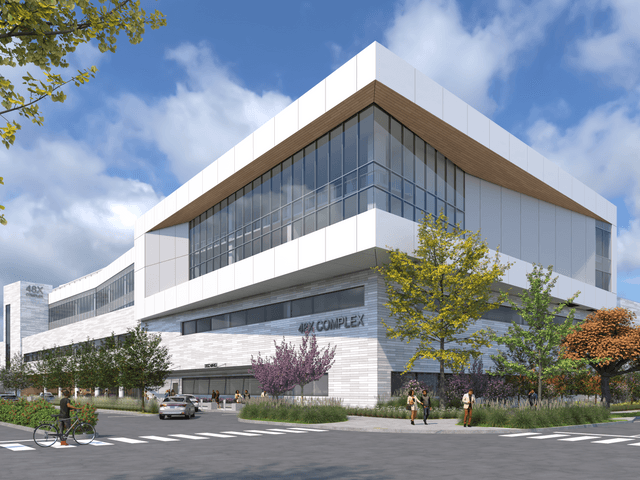

Project Description

The Sam Houston State University North Residence Hall, a 186,000 sq. ft., 5-story student housing project, exemplifies innovation and collaboration. It was decided that a prefabrication approach would save time on the overall schedule and maximize industry innovation. This pioneering project was created at the SurePods West facility and Digital Building Components facility in Phoenix, Arizona. SurePods unique prefabricated bathroom design included a shower room and a toilet room as found in many student housing building layouts. Being able to prefabricate, load in pods as the structure when up and install the bathroom systems ahead of schedule saved time, money and schedule while improving onsite safety risks. All trade partners involved in connecting and interacting with the pods were educated by SurePods in our project execution, so the guesswork of their tie-ins and interactions with the pods was eliminated.

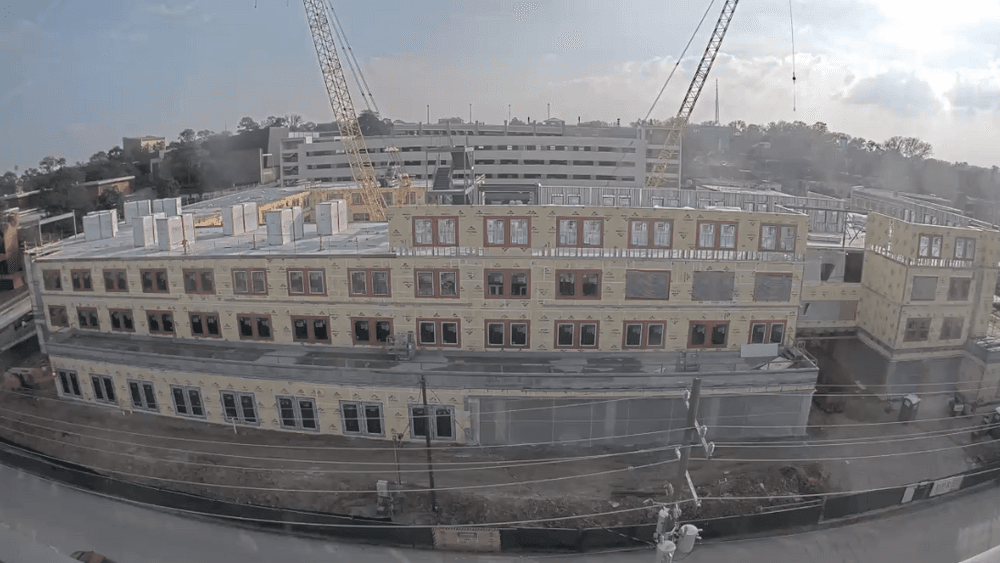

Working together with the erection of the structural wall system by Digital Building Components, allowed for a seamless just in time delivery and load in using onsite resources already in place. Teaming up with the prefabricated structural install team, SurePods was able to eliminate the need for more crews and crane time onsite, de-risking the project.

The design-build effort for panels and pods involved a detailed collaborative effort between Digital Building Components, SurePods, DPR Construction and EYP Architects. The entire team from design to general contractor to the owner understood what they were getting utilizing SurePods through constant communication, first articles pods and design reviews. No step was done in a silo and decisions were made on time to all for pods to be built in a controlled factory environment, removing craft hours from the jobsite.

Working with the design team, EYP and SurePods maximized standardization on the project, allowing for SurePods to produce a high quality, repeatable product for the job. This ensures quality, speed and schedule certainty unseen with traditionally stick built bathrooms.